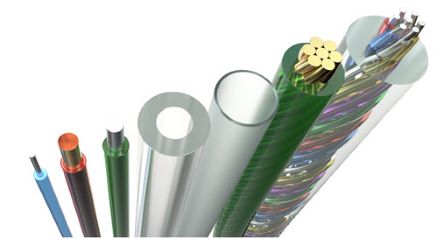

Layered for function

At Alleima, we recognize that surface coatings are essential to the performance and reliability of products and components. Our comprehensive portfolio of polymer and PTFE coatings is engineered to meet the exacting standards of the medical device industry. These coatings enhance insulation, lubricity, wear resistance, and identification—while ensuring tight dimensional tolerances and proven biocompatibility. Every solution is tailored to advance the safety, functionality, and manufacturability of your devices.

Our expertise

We offer a wide range of base, top, and bond coat materials, applied through advanced reel-to-reel and flooded coating processes. Our capabilities include:

Base coats: Polyimides (240°C), Polyurethane (155°C and 180°C, solderable), Polyester-imide (TRI-2-SOD, 180°C), Polyester (Isonel, Polyclad, 200°C), and Polyvinyl Acetal (Formvar, 105°C)

Top coats: Polyamide (Nylon) and Polyamide-imide (Aminide) for enhanced lubricity and surface leveling

Bond coats: Epoxy, Polyamide, and Polyamide-imide—available in heat- or solvent-activatable versions for coil joining and multi-wire configurations

PTFE coatings: Applied to wire sizes from 0.025 to 0.76 mm, with thicknesses from 0.0025 to 0.025 mm. Available in clear, green, blue, and custom colors

Color coding: Pigment-modified coatings for wire identification, with up to 30 standard and custom tones

All coatings can be provided in accordance with NEMA MW1000 standards, with tighter tolerances and thinner layers available upon request. Our in-house development and testing ensure that each coating stack is optimized for downstream processing, product performance, and regulatory compliance.

Learn more about our coatings

Alleima offers bondable coatings that can be applied directly to bare wire or as a secondary layer over any of our insulation options. Coating thickness can be tailored to standard NEMA or JIS builds, or adjusted to meet your specific requirements.

If your application demands a specialized coating or insulation, our experts will collaborate with you to develop a customized solution. For example, we have engineered low out-gassing, high-temperature, self-bondable coatings for the hard disk drive industry—minimizing contamination and optimizing resonance performance.

| Designation | Description | Maximum usage temperature* | Bonding technique |

|---|---|---|---|

| Bond B | Thermoplastic polyvinyl butyral | 100°C (210°F) | Methanol, acetone or heat activated |

| Bond CJL | Thermoplastic polyester | Acetone, methyl ethyl ketone or heat activated | |

| Bond E1 | Thermoplastic epoxy | 130°C (265°F) | Acetone, MEK or heat activated |

| Bond MA | Thermoplastic polyamide | 155°C (310°F) | Methyl alcohol, isopropyl alcohol or heat activated |

| Bond TT | Thermoplastic polyamide | Isopropyl alcohol or heat activated | |

| Bond XTS | Thermosetting epoxy | 155°C (310°F) | MEK or heat activated |

| Bond XTC | Thermoplastic polyamide | 200°C (390°F) | Heat activated |

| Bond MA50** | Thermoplastic polyamide | 200°C (390°F) | Methyl alcohol or heat activated |

| Sulfones | |||

| Tecothane |

* The maximum usage temperature is based on the temperature at which the adhesive retains 5 - 10% of it's room temperature strength.

** Contact us for more information.

Metallic coatings

Alleima offers a range of surface treatments and advanced metallic coatings, including anodizing, electroplating, and electropolishing. Our standard electroplating treatments include silver, rhodium, palladium, copper, gold, fine gold, tin, and nickel. We specialize in electroplating micro components, delivering high-performance coatings even on the smallest parts. Custom electroplating solutions are available on request to meet your specific requirements. In addition, we provide cladding and cladded alloy options for enhanced material performance. With Alleima, you gain precise, reliable metallic coatings engineered for demanding applications..

Alleima offers a range of surface treatments and advanced metallic coatings, including anodizing, electroplating, and electropolishing. Our standard electroplating treatments include silver, rhodium, palladium, copper, gold, fine gold, tin, and nickel. We specialize in electroplating micro components, delivering high-performance coatings even on the smallest parts. Custom electroplating solutions are available on request to meet your specific requirements. In addition, we provide cladding and cladded alloy options for enhanced material performance. With Alleima, you gain precise, reliable metallic coatings engineered for demanding applications..

ETFE polymer coating is a biocompatible coating added in an extrusion process when precise coating is required. It can be made in any wall thickness larger than 0,02 mm (0.0008”) where typical tolerances are ± 0,01mm (±0,0004”). Thinner wall thickness on request.

With our very good concentricity and dimensional control we can offer an extrusion process that’s not a common capability globally. Extruded coating with an ETFE polymer coating is offered on most metals over 0.07mm (0.003”) in diameter.

The ETFE polymer coating is a copolymer of ethylene and tetrafluoroethylene. ETFE resins has excellent resistance to abrasion and stress cracking.

The ETFE coating is used in extrusion straight tubing, coated wire and cable. It’s used in applications where electrical isolation at elevated temperatures, high degree of mechanical toughness, chemical inertness and/or low friction is required.

Typical applications include sensing leads, handheld devices, implants, robotic connectivity and other microelectronic medical devices since it can operate in wide-temperature ranges, has low water absorption and performs well with ETO (ethylene oxide), autoclave and gamma sterilizations.

Chemical composition

Ethylene tetrafluoroethylene >99.99% PFOA Free (Medical Grade).

Properties (Typical)

- Coating 0.02 mm - 0.1016 mm (±0.01mm)

- Thickness: 0.004” - 0.0008” (±0.0004'')

- Wire sizes: 0.075 mm to 0.7 mm (0.003” to .028”)

- Color: Transparent (colored on request)

- Density: 0.0625 lb/in3

- Melting Point: 260° C (500° F)

- Max Operating Temp: 279° C (535° F)

- Temperature range: –190 to 150º C ( –310 to 302º F)

- Dielectric Breakdown Voltage: 1.8 KV/mil

- Dielectric Constant: 2.7

- Coefficient of Friction: 0.24

- Tensile Strength: 6000 – 6100 psi

- Elongation: 300 – 400%

- Flexural Modulus: 130 – 145 ksi

- Water Absorption (24 hr): <0.01%

Alleima provide insulation coatings for temperatures up to 240°C (464°F). In addition to standard NEMA or JIS builds, we are capable of applying 'thin' and 'ultra-thin' builds of insulations. These builds are thinner than NEMA Type 1, but still meet the dielectric property and other requirements of NEMA Type 1.

Insulation coatings

| Designation | Insulation type | Thermal rating | NEMA specification |

|---|---|---|---|

| Aminide | Polyamide-imide (also usable as a top coat) | 220°C (430°F) | MW 81 |

| FEP | Florinated ethylene propylene | ||

| Formvar | Polyvinyl acetal | 105°C (220°F) | MW 15 |

| Nylon | Polyamide top coat | MW 1000 | |

| PAC-240 | Aromatic polyimide (ML) | 220°C (430°F) | MW 16, 20, 71 |

| Poly | Polyurethane | 155°C (310°F) | MW 28, 70, 80 and MW 79 on smaller AWG sizes |

| Poly/Nylon | Polyurethane with a polyamide top coat | 155°C (310°F) | MW 28, 80 |

| Poly 180B | Polyurethane | 180°C (355°F) | MW 82, 83 |

| PolyClad | THEIC modified polyester | 200°C (390°F) | MW 5 |

| PolyClad/Nylon | THEIC modified polyester with a polyamide top coat | 200°C (390°F) | MW 76 |

| PolyClad/Aminide | THEIC modified polyester with a polyamide.imide top coat | 200°C (390°F) | MW 35, 73 |

| PTFE | Polytetrafluoroethylene | ||

| Sulfones | |||

| Tecothane | |||

| Tri-2-sod | Polyesterimide | 180°C (355°F) | MW 77 |

| Tri-2-sod/Nylon | Polyesterimide with a polyamide top coat | 180°C (355°F) | MW 78 |

PTFE coating can be applied to any medical grade in size range 0.025–0.762 mm (0.001–0.030 in.). Alleima provides PTFE-coated wire with coating thickness from 0.00127 to 0.0127 mm (0.00005 to 0.0005 in.). Typical coloring of the PTFE c