Developed for pinpoint steering.

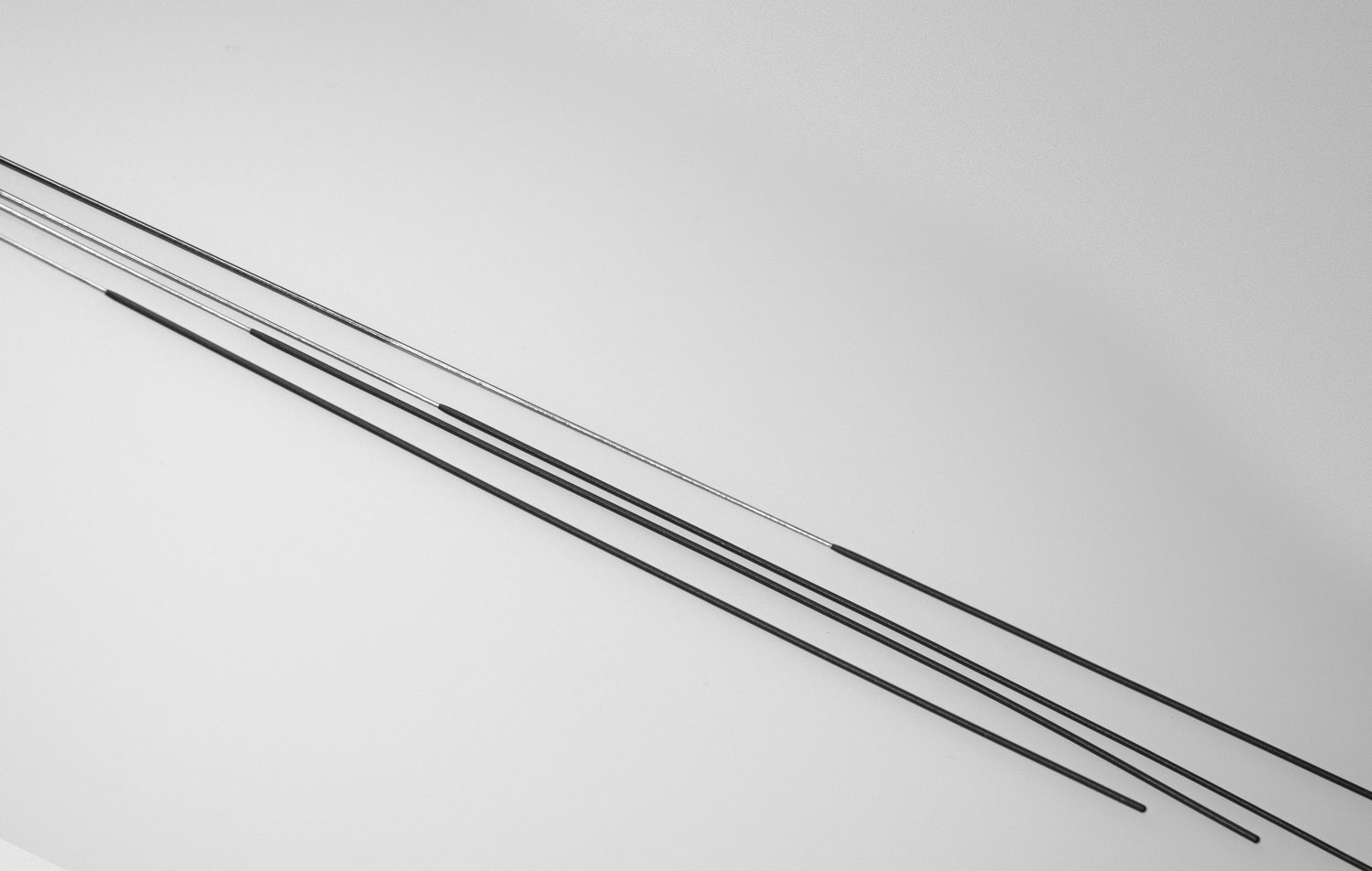

Guidewires engineered for ultra-smooth control

At Alleima, every guidewire is built on a precision-engineered nitinol core, delivering exceptional strength, flexibility, and reliability. From this foundation, you can tailor coating options, tip flexibility, radiopacity, and accessories to suit your specific procedural requirements.

Our advanced surface treatments are designed to minimize friction within catheters, enabling smooth and accurate manipulation of the guidewire. Enhanced surface structures also improve grip, providing precise control during procedures and reducing the risk of slippage after placement.

Below are the core dimensions and configuration options available across all guidewire variants—your foundation for a fully customized solution.

Core wire features

|

Feature |

Specification |

| Core wire | Nitinol, Ø 0.889 mm (0.035 inch) standard (others on request) |

| Lenths (cm) | 50, 60, 65, 70, 75, 80, 100, 125, 150, 180, 300, 400, 460 (± 5 mm tolerance) -- others on request |

| Flexibity | One or both sides |

| Tip angle |

60° J standard (others on request) |

| Transport hose material | PP or HDPE |

| * custom specifications available upon request | |

Our guidewires at a glance

| Variant | Jacket / Shaft | Surface | Tip | X-ray visibility | Markers |

|---|---|---|---|---|---|

| Standard | PTFE or PU-extruded | Hydrophobic / Hydrophilic | Flexible NiTi (straight or J) | Tip (PTFE) / Full (PU) | – |

| PU-Tip | PTFE | Hydrophobic | 5 cm high-flex PU tip | Tip only | – |

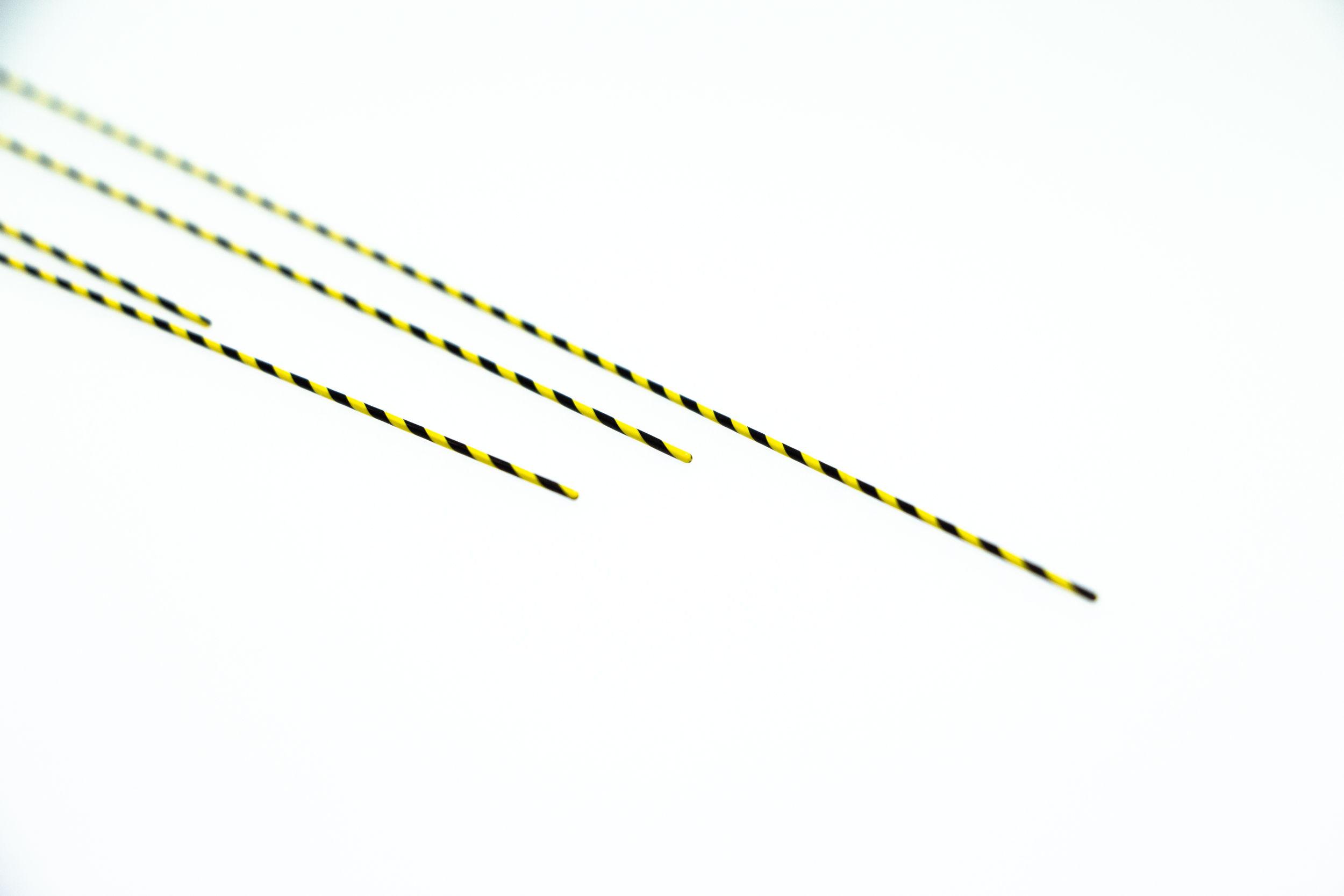

| SKAL | PTFE | Hydrophobic | 5 cm flexible (PU opt.) | Tip only | Platinum at 1 cm intervals |

| Extruded | PU-extruded | Hydrophilic | Flexible tip | Whole shaft | – |

| Glider | PTFE shaft + shrink section | Hydrophobic | PU tip + PTFE transition | Tip only | – |

| OSD | Bare NiTi shaft | – | PU tip | Tip only | – |

Guidewire gallery

Click through the gallery to get a closer look at each guidewire variant.

Built for everyday access.

For the most precise marking.

Ultimate hydrophilic performance.

For effortless push-and-glide control.

Made for Oesophagus-Bougies and Oesophagus-Stent-Systems.