SAF™ 2906 is a high-alloy duplex (austenitic-ferritic) stainless steel with excellent general corrosion resistance in various corrosive environments. The grade is characterized by:

- Excellent corrosion resistance to ammonium carbamate solutions both with oxygen and with little or no oxygen

- Excellent resistance to caustic environments, also in the presence of contaminants such as chlorides

- Excellent resistance to intergranular corrosion

- Excellent resistance to pitting and crevice corrosion

- High resistance to stress corrosion cracking (SCC)

- Good weldability

- Very high mechanical strength. The proof strength is about three times as high as for conventional austenitic stainless steels.

Standards

- UNS: S32906

- EN Number: 1.4477

Product standards

- Seamless tube and pipe: ASTM A789, A790

- Bar steel: ASTM A479

- Plate: ASTM A240

Approvals

- Approved by the American Society of Mechanical Engineers (ASME) for use in accordance with ASME Boiler and Pressure Vessel Code, Section VIII, div. 1 and 2.

- PED (Pressure Equipment Directive) PED 2014/68/EU and AD2000 Merkblatt W2: Particular Material Appraisal (PMA), Austenitic-ferritic steel SAF™ 2906.

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | N |

|---|---|---|---|---|---|---|---|---|---|

| ≤0.030 | 0.3 | 1.0 | ≤0.030 | ≤0.015 | 29 | 7 | 2.3 | ≤0.80 | 0.35 |

Applications

Typical applications for SAF™ 2906 are:

- Urea production: the material can be used successfully for all components in the urea plant, such as stripper tubes, condenser tubes, high-pressure piping etc.

- Caustic soda production: the material is suitable for use in piping systems from the cells up to the evaporation plant. It is also an excellent choice for very aggressive conditions, such as the evaporator tubes, in both diaphragm and membrane process.

- Alumina production: heat exchanger tubes and piping in the digestion of alumina

- Environments where high resistance to pitting and crevice corrosion is required

Forms of supply

SAF™ 2906 can be supplied as seamless tube and pipe. Tubes can be supplied straight or U-bent. SAF™ 2906 is supplied in dimensions up to 457.2 mm (18 in.) outside diameter. They are delivered in the solution annealed condition and either white pickled or bright annealed.

Other product forms

- Bar steel

- Fittings and flanges

- Plate, sheet and strip

- Forged products

Corrosion resistance

Production of urea

SAF™ 2906 was originally developed for use in the urea synthesis process, which operates under very high pressures and temperatures. In the high-pressure section, the presence of the highly corrosive compound ammonium carbamate can cause significant corrosion issues if inappropriate materials are used. SAF™ 2906 is optimized for superior corrosion resistance against carbamate solutions with low oxygen content, thereby enhancing both plant safety and productivity.

Caustic environment

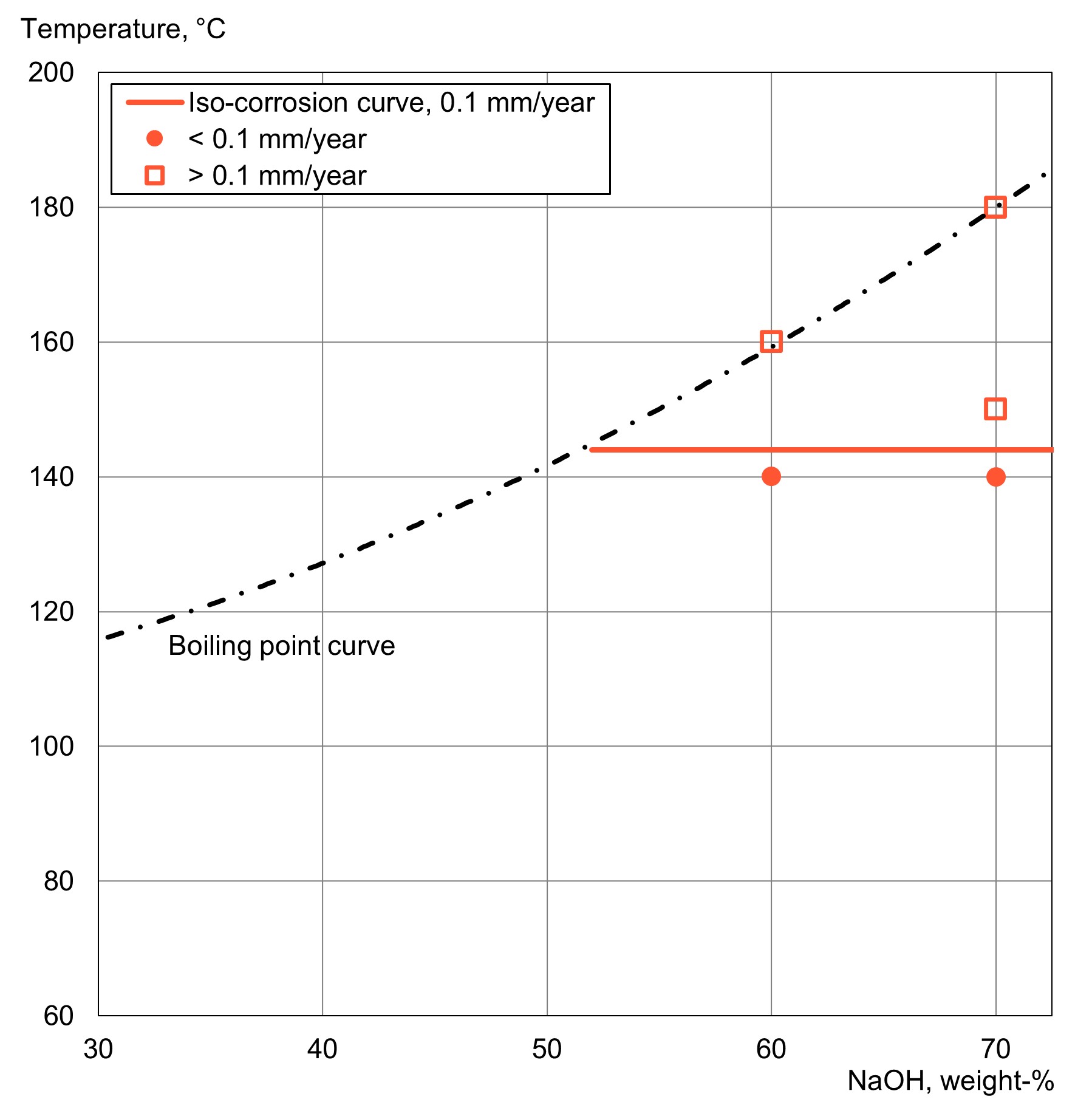

SAF™ 2906 has, owing to its high chromium content, a very good resistance in caustic environments. For pure caustic soda, the performance of SAF™ 2906 can be observed in the iso-corrosion diagram (0.1 mm/year), see Figure 1. In the production of caustic soda, however, impurities in the form of chlorides and chlorates are present. Usually, in the caustic soda manufacturing process Ni200 or high nickel alloys are used, especially in critical equipment such as the evaporators. Results of corrosion tests in sodium hydroxide (NaOH) containing different amounts of sodium chloride (NaCl) and sodium chlorate (NaClO3), similar to the content found in the evaporation plants of diaphragm and membrane processes, are presented in Tables 1 and 2. The results clearly indicate the good performance of SAF™ 2906 in caustic environments.

Table 1. Performance in caustic environments - Diaphragm process

| Grade | Environment | Temperature, °C (°F) | Corrosion rate mm/year |

|---|---|---|---|

| SAF™ 2906 | 10% NaOH, 2% NaCl, 800 ppm ClO3- | 100 (212) | < 0.01 |

| Boiling | < 0.01 | ||

| 50% NaOH, 7% NaCl, 800 ppm ClO3- | 100 (212) | < 0.01 | |

| Boiling | 0.016 | ||

| Sanicro® 28 | 10% NaOH, 2% NaCl, 800 ppm ClO3- | 100 (212) | < 0.01 |

| Boiling | < 0.01 | ||

| 50% NaOH, 7% NaCl, 800 ppm ClO3- | 100 (212) | < 0.01 | |

| Boiling | 0.34 | ||

| Ni200 | 10% NaOH, 2% NaCl, 800 ppm ClO3- |

100 (212) | < 0.01 |

| Boiling | < 0.01 | ||

| 50% NaOH, 7% NaCl, 800 ppm ClO3- | 100 (212) | < 0.01 | |

| Boiling | 0.15 |

Table 2. Performance in caustic environments - Membrane process

| Grade | Environment | Temperature | Corrosion rate mm/year |

|---|---|---|---|

| SAF™ 2906 | 32%NaOH + 30 ppm Cl- + 20 ppm NaClO3 | Boiling | < 0.01 |

| 50%NaOH + 30 ppm Cl- + 20 ppm NaClO3 | Boiling | < 0.01 | |

| Ni200 | 32%NaOH + 30 ppm Cl- + 20 ppm NaClO3 | Boiling | < 0.01 |

| 50%NaOH + 30 ppm Cl- + 20 ppm NaClO3 | Boiling | < 0.01 |

Figure 1. Iso-corrosion diagram for SAF™ 2906 in pure NaOH, naturally aerated solution.

Pitting and crevice corrosion

SAF™ 2906 has a carefully balanced composition with a high chromium and nitrogen content and a moderate amount of molybdenum. This gives the material a high resistance to localized corrosion caused by chlorides. The PRE number (Pitting Resistance Equivalent) is an index for comparing pitting corrosion resistance.

The PRE is defined as, in weight-PRE = %Cr + 3.3 x %Mo + 16 x %N

A very severe test for pitting or crevice corrosion is the ASTM G48 test, i.e. immersion in 6 % FeCl3. Results for pitting test according to modified method A and crevice corrosion testing according to method B, are presented in Table 3. The crevice corrosion test was performed with a crevice specified in the MTI-2 procedure, where an artificial crevice is mounted on the sample with a torque of 0.28 Nm. The critical pitting temperature (CPT) and the critical crevice temperature (CCT) are the temperatures where pitting or crevice corrosion starts to develop on the material.

Table 3. PRE, CPT and CCT values

| Grade | PRE (min.) | CPT, °C (°F) | CCT, °C (°F) |

|---|---|---|---|

| SAF™ 2906 | 41.5 | 75 (167) | 42.5 (109) |

| SAF™ 2507 | 42.5 | 80 (176) | 50 (122) |

| SAF™ 2205 | 35 | 30 (86) | 18 (64) |

| ASTM 316L | 26 | <10 (50) | <10 (50) |

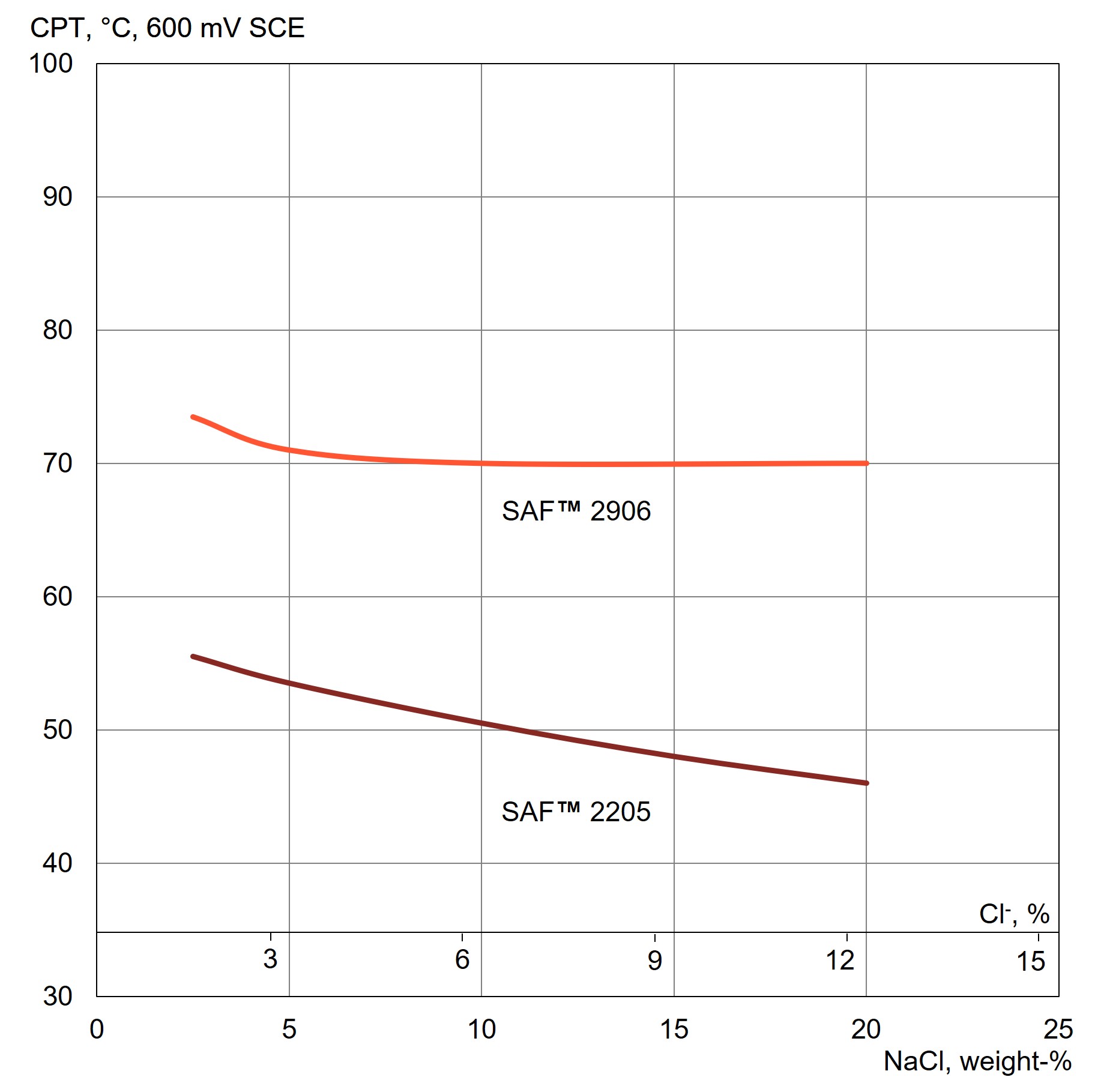

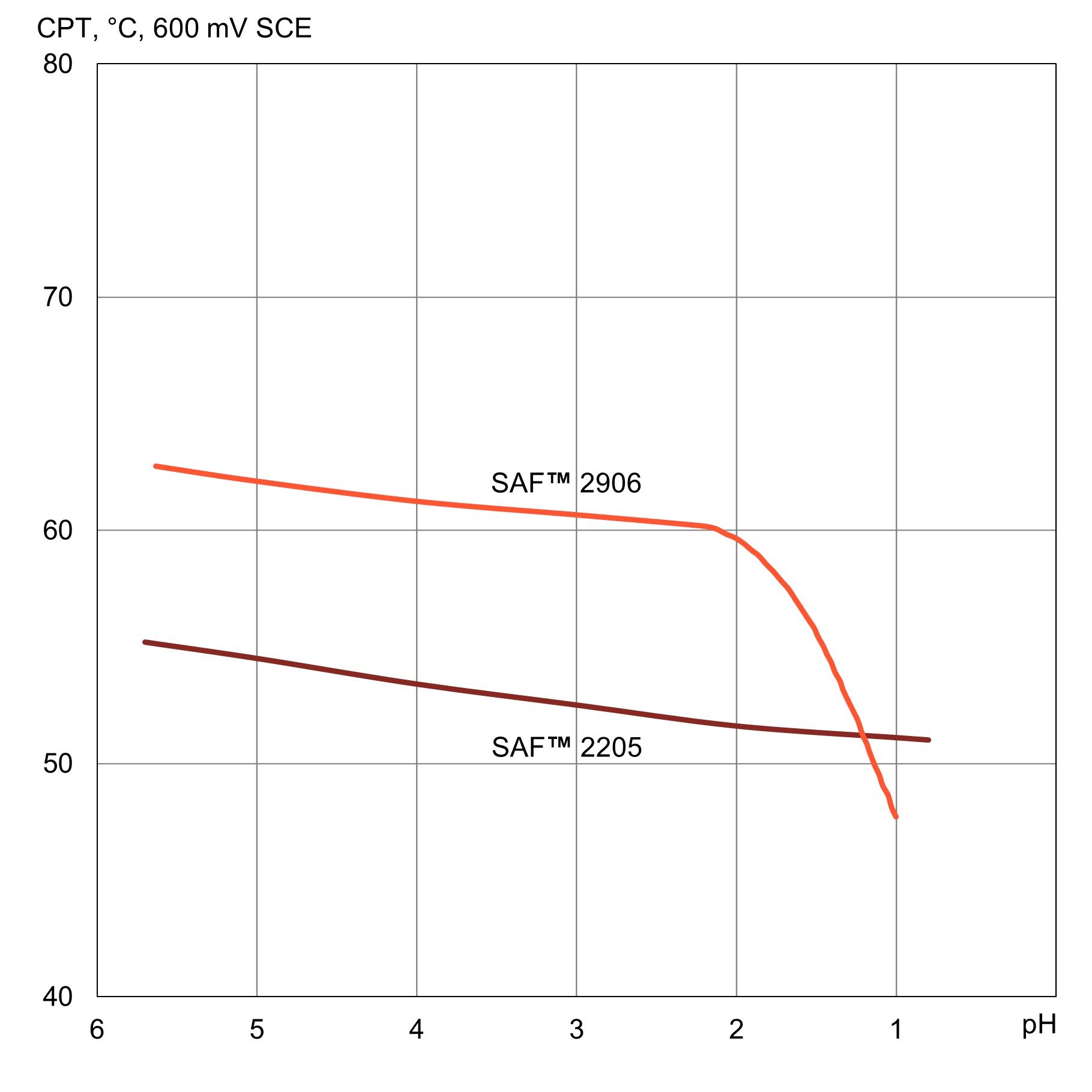

Potentiostatic tests in solutions with different chloride contents are reported in Figure 2. Figure 3 shows the effect of increased acidity. In both cases the applied high potential, 600 mV SCE, corresponds to very harsh conditions, thus resulting in conservative data with a lower critical temperature compared with most practical situations.

Figure 2. Critical pitting temperature (CPT) at varying concentrations of sodium chloride, from 3 to 25 % (potentiostatic determination at +600 mV SCE with surface ground to 600 grit paper).

Figure 3. Critical pitting temperature (CPT) in 3% NaCl with varying pH (potentiostatic determination at +600 mV SCE with surface ground to 600 grit paper).

Stress corrosion cracking (SCC)

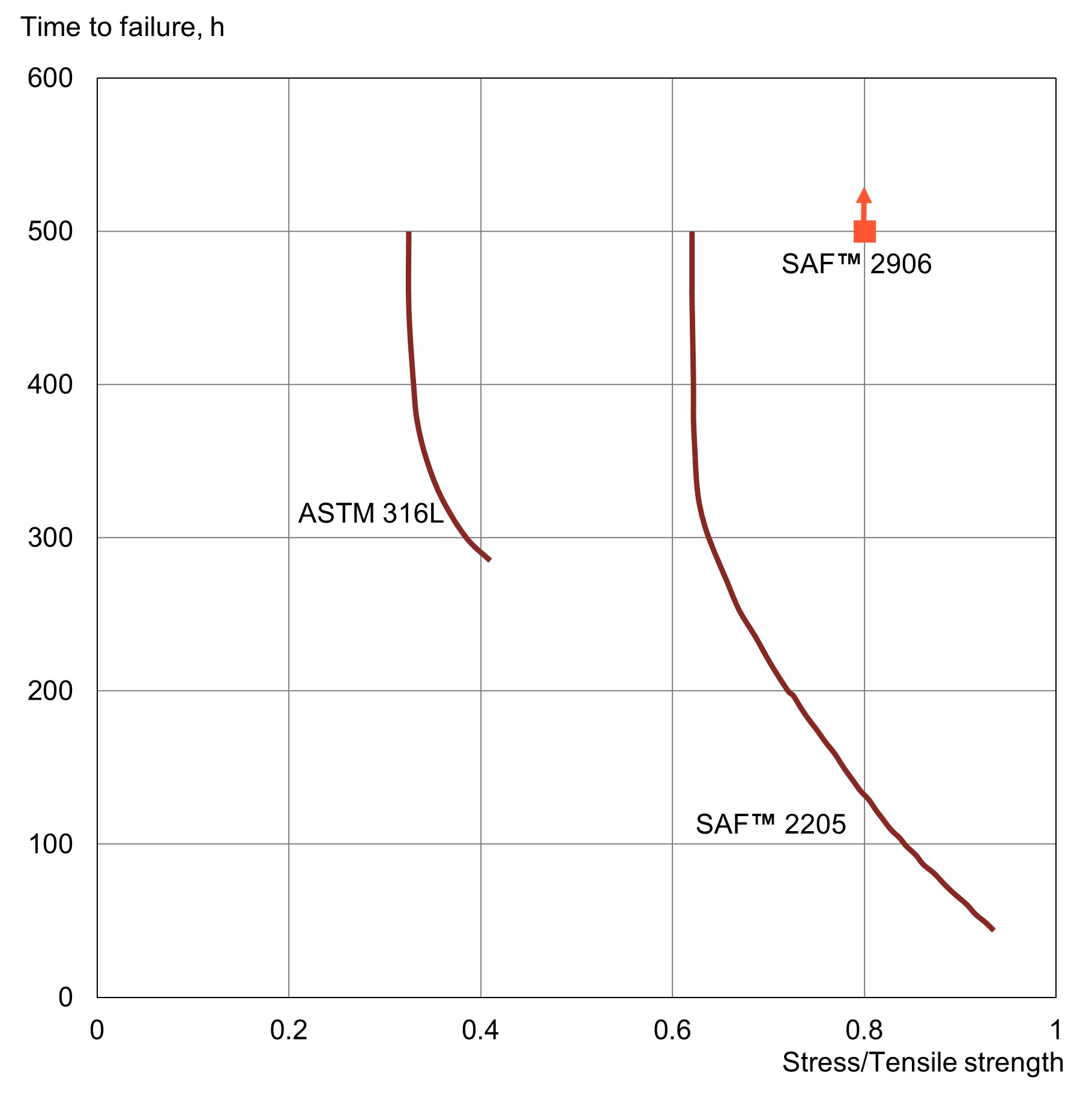

SAF™ 2906 has excellent resistance to chloride induced stress corrosion cracking (SCC). The resistance of various alloys to stress corrosion cracking (SCC) determined by constant load testing in aerated 40 % CaCl2, pH 1.5, at 100 °C (212 °F), (modified ASTM G36 method) is shown in Figure 4.

Figure 4. Constant load testing of SAF™ 2906 and some other alloys in 40% CaCl2 , pH 1.5, at 100°C (212°F). Time to failure vs. applied stress in percentage of tensile strength is shown.

Nitric acid

SAF™ 2906 offers good resistance to nitric acid due to its balanced composition of chromium and molybdenum. When both excellent resistance to nitric acid and pitting resistance are required, SAF™ 2906 is a suitable choice. Additionally, it provides excellent resistance to stress corrosion cracking (SCC) and possesses high mechanical strength, which can be a benefit in nitric acid plants.

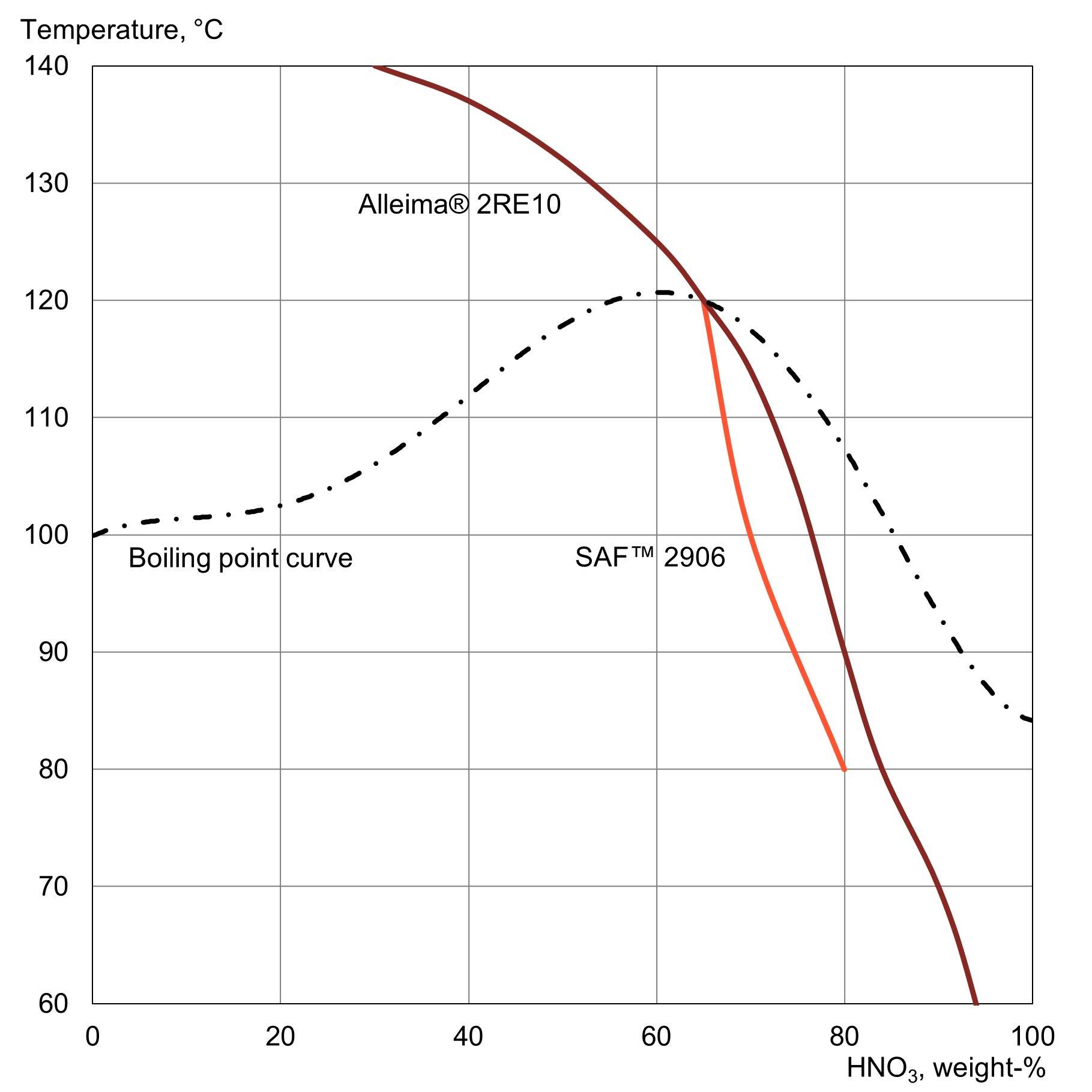

The iso-corrosion diagram, see Figure 5, shows the performance of the material compared to Alleima® 2RE10, a high purity austenitic grade widely used for nitric acid.

Figure 5. Iso-corrosion diagram for SAF™ 2906 and Alleima® 2RE10 in a naturally aerated, stagnant solution of nitric acid. The curves represent a corrosion rate of 0.1 mm/year.

Mechanical properties

The following figures apply to material in the solution annealed condition. If SAF™ 2906 is exposed for prolonged periods to temperature ranges exceeding 280 °C (540 °F), the microstructure changes, which results in a reduction in toughness. This does not necessarily affect the behavior of the material at the operating temperature. The listed values are guaranteed for tube and pipe.

At 20 °C (68 °F)

| Wall thickness | Proof strength | Tensile strength, | Elong | Hardness |

|---|---|---|---|---|

| Rp0.2 a) | Rm | Ab) | ||

| mm | MPa | MPa | % | HRC |

| Min. | Min. | Min. | Max. | |

| <10 | 650 | 800 | 25 | 32 |

| ≥10 | 550 | 750 | 25 | 32 |

1 MPa = 1 N/mm2

a) Rp0.2 corresponds to 0.2% offset offset yield strength.

b) Based on L0 = 5.65 √S0 where L0 is the original gauge length and S0 the original cross-section area.

| Wall thickness | Proof strength | Tensile strength | Elong | Hardness |

|---|---|---|---|---|

| Rp0.2 | Rm | Ab) | ||

| in. | ksi | ksi | % | HRC |

| Min. | Min. | Min. | Max. | |

| <0.4 | 94 | 116 | 25 | 32 |

| ≥0.4 | 80 | 109 | 25 | 32 |

a) Rp0.2 corresponds to 0.2% offset offset yield strength.

b) Based on L0 = 5.65 √S0 where L0 is the original gauge length and S0 the original cross-section area.

At high temperatures

| Temperature | Wall thickness | Proof strength | Tensile strength, | Elong |

|---|---|---|---|---|

| Rp0.2 a) | Rm | Ab) | ||

| °C | mm | MPa | MPa | % |

| Min. | Min. | Min. | ||

| 100 | <10 | 550 | 750 | 25 |

| ≥10 | 500 | 730 | 25 | |

| 200 | <10 | 470 | 720 | 25 |

| ≥10 | 430 | 700 | 25 | |

| 300 | <10 | 450 | 710 | 25 |

| ≥10 | 410 | 690 | 25 |

| Temperature | Wall thickness | Proof strength | Tensile strength | Elong |

|---|---|---|---|---|

| Rp0.2 | Rm | A2” | ||

| °F | in. | ksi | ksi | % |

| Min. | Min. | Min. | ||

| 200 | <0.4 | 80 | 109 | 25 |

| ≥0.4 | 73 | 106 | 25 | |

| 400 | <0.4 | 68 | 104 | 25 |

| ≥0.4 | 62 | 101 | 25 | |

| 600 | <0.4 | 65 | 103 | 25 |

| ≥0.4 | 59 | 100 | 25 |

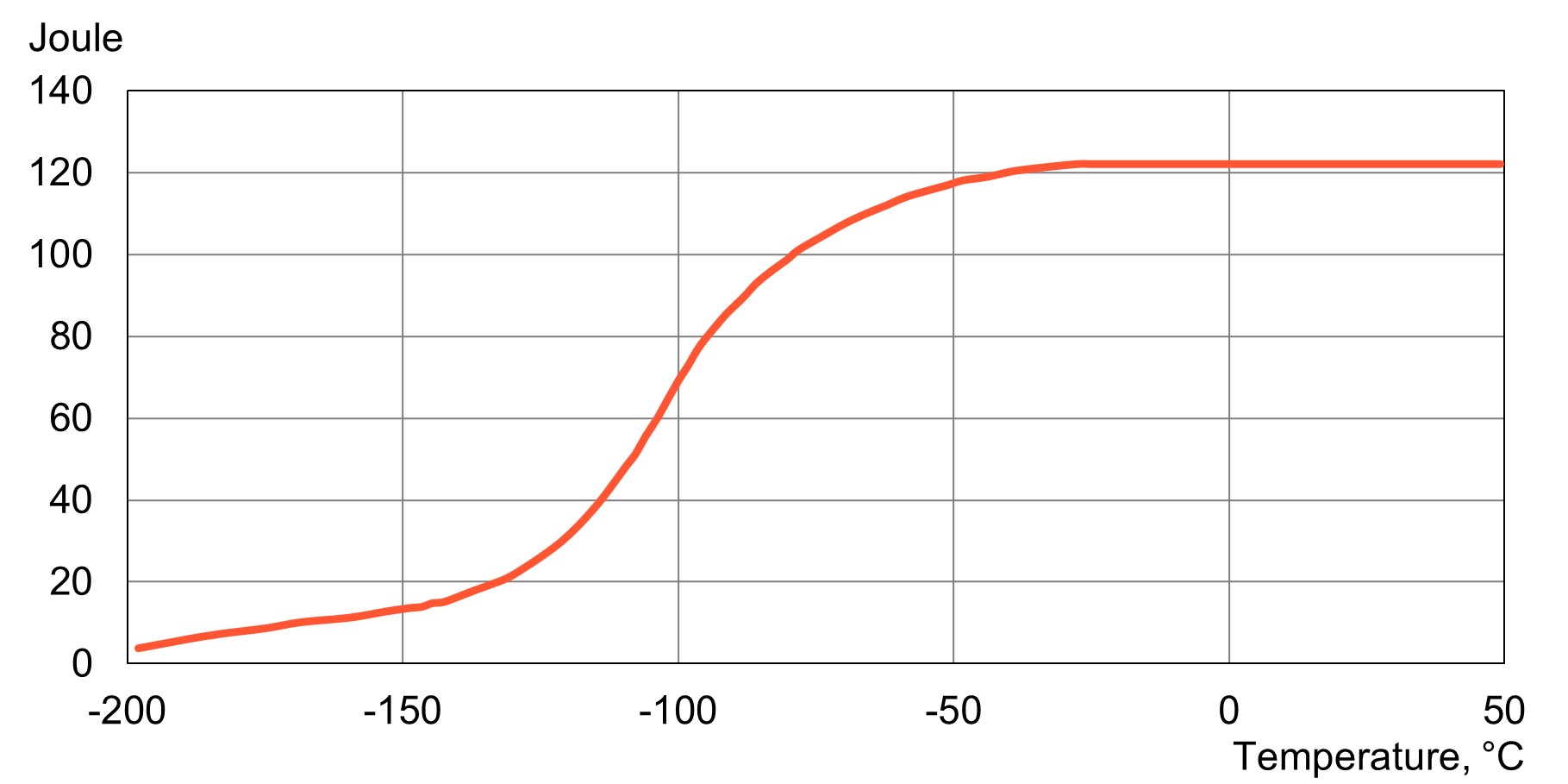

Impact strength

SAF™ 2906 possesses good impact strength both at room temperature and at low temperatures. The ductility to brittle transition temperature is approximately -100 °C (-50 °F). Figure 6 shows the typical impact energy for SAF™ 2906.

Figure 6. Typical impact energy curve for SAF™ 2906 using half size (5 x 10 mm) Charpy V specimens (average of 3 at each temperature).

Physical properties

Density: 7.7 g/cm3, 0.28 lb/in3

Thermal conductivity

| Metric units | |

| Temperature, °C | W/m °C |

| 20 | 13 |

| 100 | 14 |

| 200 | 16 |

| 300 | 18 |

| 400 | 19 |

| Imperial units | |

| Temperature, °F | Btu/ft h°F |

| 68 | 7 |

| 200 | 8 |

| 400 | 9 |

| 600 | 10 |

| 800 | 11 |

Specific heat capacity

| Metric units | |

| Temperature, °C | J/kg °C |

| 20 | 470 |

| 100 | 500 |

| 200 | 530 |

| 300 | 560 |

| 400 | 600 |

| Imperial units | |

| Temperature, °F | Btu/ft h°F |

| 68 | 0.11 |

| 200 | 0.12 |

| 400 | 0.13 |

| 600 | 0.14 |

| 800 | 0.14 |

Modulus of elasticity (x103)

| Metric units | |

| Temperature, °C | MPa |

| 20 | 200 |

| 100 | 194 |

| 200 | 186 |

| 300 | 180 |

| Imperial units | |

| Temperature, °F | ksi |

| 68 | 29.0 |

| 200 | 28.2 |

| 400 | 26.9 |

| 600 | 26.0 |

Thermal expansion

SAF™ 2906 has a coefficient of thermal expansion close to that of carbon steel. This gives SAF™ 2906 definite design advantages over austenitic stainless steels. The values given in the table are average values in the temperature ranges.

| Metric units, x10-6/°C | ||||

| Temperature, °C | 30-100 | 30-200 | 30-300 | 30-400 |

| SAF™ 2906 | 11.5 | 12.0 | 12.5 | 12.5 |

| Carbon steel | 12.5 | 13.0 | 13.5 | 14.0 |

| ASTM 316L | 16.5 | 17.0 | 17.5 | 18.0 |

| Imperial units, x10-6/°F | ||||

| Temperature, °F | 86-200 | 86-400 | 86-600 | 86-800 |

| SAF™ 2906 | 6.5 | 7.0 | 7.0 | 7.0 |

| Carbon steel | 7.0 | 7.0 | 7.5 | 8.0 |

| ASTM 316L | 9.5 | 9.5 | 10.0 | 10.0 |

Resistivity

| Metric units | |

| Temperature, °C | μΩm |

| 20 | 0.81 |

| Imperial units | |

| Temperature, °F | μΩinch |

| 68 | 31.9 |

Fabrication

Hot working and heat treatment

The tubes are normally delivered in the heat treated condition. If additional heat treatment is needed after further processing, the following is recommended.

Annealing

1040 – 1080 °C (1900 – 1980 °F), rapid cooling in air or water.

Bending

The force needed for bending SAF™ 2906 is higher than that for standard austenitic stainless steels which is a natural consequence of the higher yield strength.

Expanding

Compared with austenitic stainless steels, SAF™ 2906 has a higher proof and tensile strength. This must be kept in mind when expanding tubes into tubesheets. Normal methods can be used, but the expansion requires higher initial force and should be undertaken in a one step operation. As a general rule, tube to tubesheet joints should be welded to ensure a leak free joint.

Machining

Being a dual phase material (austenitic-ferritic) SAF™ 2906 will present a different wear picture from that of a single phase material like Alleima® 2RE69. The cutting speed must therefore be lower than that recommended for austenitic grades. Further information is available on request.

Welding

The weldability of SAF™ 2906 is good. Welding must be carried out without preheating and subsequent heat treatment is normally not necessary. Suitable method of fusion welding is gas tungsten arc welding GTAW/TIG with shielding gas of Ar + 2 % N2. For tube to tubesheet welding, it is recommended to use Ar + 3 % N2 as shielding gas to have proper weld metal structure.

For SAF™ 2906, heat input of 0.2-1.5 kJ/mm and interpass temperature of <150 °C (300 °F) are recommended.

Recommended filler metals

GTAW/TIG welding

Exaton 29.8.2.L wire or strip electrodes are recommended for overlay welding of tubesheets and high-pressure vessels in cases where corrosion resistance, equal to that of SAF™ 2906, is required.

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.